What Is a Mooring Chain?

A mooring chain is a heavy-duty chain that links floating structures offshore platforms, FPSOs (Floating Production Storage and Offloading), ships, buoys, etc. to anchors on the seabed. In contrast to the temporary anchor chains for ship mooring, mooring chains are subjected to permanent or long term application in a mooring system, and they are expected to endure long-term immersion in seawater, high tensile loads, corrosion and severe marine environment. The chain's weight itself makes a catenary (curved) shape that dissipates waves, wind and tides and it helps stabilizing the tethered structure.

Mooring chains are used in:

Ship mooring systems

Offshore oil & gas platforms

Floating production storage and offloading units (FPSO)

Single point mooring (SPM) systems

Buoys and floating docks

Main Types of Mooring Chains

There are different types of mooring chains, designed for various applications and operating conditions.

1. Stud Link Mooring Chain

Stud-Link Mooring Chains: These are the standard heavy-duty chains and are what stud-link chains are made up with a stud (which is a metal bar) running through the inside width of every link. It prevents bending laterally and twisting when subjected to high tension and this is the reason why they are suitable for deepwater, offshore oil rig/platform, floating wind turbine .Their superior strength and fatigue resistance make them the best option for high consequence offshore services

Advantages:

Higher strength and stability

Better load distribution

Reduced risk of link deformation

Typical Use:

Permanent mooring systems

Offshore platforms and FPSOs

Heavy-duty harbor moorings

2. Studless Mooring Chain

Studless Mooring Chains: These chains are lighter and more flexible than stud-link chains as they do not have an internal stud. Although they have lower strength, they are more cost-effective and can be handled more easily, which makes them applicable for use in shallow-water environments such as buoy mooring, small vessels, and coastal facilities.

Advantages:

Lower weight

Easier inspection and maintenance

Better fatigue performance in some applications

Typical Use:

Offshore mooring systems

Deepwater moorings

Situations where weight reduction is critical

Grades of Mooring Chain

Mooring chains are manufactured in different strength grades to meet various load requirements:

| Grade | Tensile Strength | Impact Test | Fatigue Performance |

R3 | ≈ 690 MPa | –20°C | Standard |

| R3S | ≈ 720 MPa | –20 /–40°C | Improved |

| R4 | ≈ 860 MPa | –20 /–40°C | High |

| R4S | ≈ 900 MPa | –40°C | Very High |

| R5 | ≥ 1000 MPa | –40°C | Ultra High |

Higher grades allow smaller chain diameters for the same load capacity, reducing system weight while maintaining safety.

Materials and Manufacturing Process

| Grade | Steel Type | Alloy System |

R3 | High-toughness C-Mn steel | C–Mn + micro alloy |

| R3S | Low alloy toughness steel | Mn–Ni–Cr–Mo |

| R4 | Alloy quenched & tempered steel | Ni–Cr–Mo alloy steel |

| R4S | High-purity Ni–Cr–Mo steel | Vacuum refined |

| R5 | Ultra high strength alloy steel | Ni–Cr–Mo–V alloy |

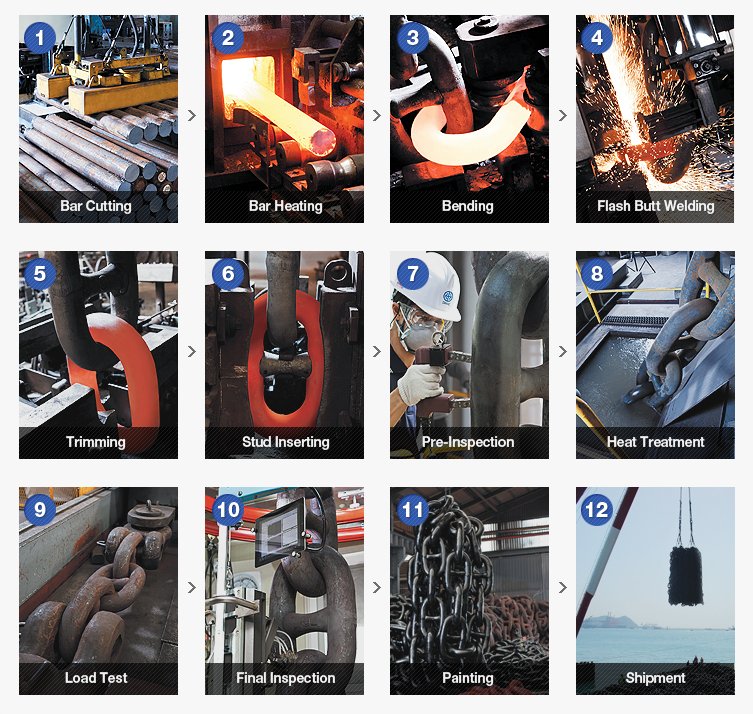

Manufacturing Process

International Standards for Mooring Chains

Mooring chains must comply with strict international standards to ensure safety and reliability:

DNV Rules – Offshore mooring chain certification

ABS / LR / BV / CCS – Classification society approvals

Third-party inspection and class certification are often mandatory for offshore projects.

Key Applications of Mooring Chains

Ship Mooring: Used in ports and terminals to secure vessels alongside quays, dolphins, or buoys.

Offshore Oil & Gas: Essential for mooring semi-submersibles, FPSOs, and drilling rigs under extreme environmental loads.

Single Point Mooring (SPM): Critical component connecting tankers to offshore loading systems.

Buoys and Floating Structures: Provide long-term stability for navigation buoys, floating docks, and marine aquaculture systems.

How to Choose the Right Mooring Chain?

When selecting a mooring chain, consider the following factors:

(1) Required breaking load and safety factor

(2) Water depth and environmental conditions

(3) Fatigue life requirements

(4) Compatibility with shackles and connectors

(5) Applicable standards and class approvals

(6) Working with an experienced marine chain manufacturer ensures the chain meets both technical and regulatory requirements.

Essential Maintenance Tips

To make sure the mooring chains are long- lasting and dependable, the maintenance should be regular:

1. Cleaning: Clean the sediment and marine biofouling with high pressure water guns. For resistant corrosion, sand or steel wire brush.

2. Lubrication: Apply lubricants on the moving components to deter rust and lessen the wear.

3. Viewing: Perform visual inspections for cracking, eformations and corrosion on a periodic basis.Tensile testing shall be also performed to verify the chain is still safe to be used at its design load.

Conclusion

Mooring chain is very important for marine/offshore security. Knowing the variations in the types, grades, materials, standards and more enables buyers to better understand what they are buying and allows them to get the most out of system performance.For marine equipment suppliers and shipyards, certified high-quality mooring chain is a crucial factor in procuring international projects and execution of operational security.

Leave A Message